Producers’s professional needs are in the middle of TWT’s innovations. From 27 to 31 may, at Ligna in Hannover at Hall027-Stand K32 some previews will be presented. They are the result of the researching activity and the development of the last two years, like the new cut geometries, applied to all the tools.

Among the innovations there is TWTWeb, a software for the spare parts and commercial aspects management.

TWT decided to tackle with determination the different challenges set by the “Industria 4.0”, aiming at realising, for itself and for the clients, a version of the future in which people, informations and installations will be more related. “We are sure that the competition and the efficiency of the manufacturing industry and of producers of wooden windows will be born from 2 factors: innovation- of product,process, ecc.- and digital technology.” underline Filippo Pellitteri, President of the company in Trentino. “In the last two years, the company has been occupied in an intense activity of Research&Development that will culminate at the end of 2019, or beginning of 2020, with the launch on the market of the wooden window with a new tool conception, that I can define revolutionary. In May Ligna will be the ideal occasion to present some preview with the new cut geometries which will be applied on every our toll, guaranteeing a better finishing touch and a better efficiency.”

A global offering with innovation

The will of offering at our clients new and ahead of your time tools, in order to answer the requests of today’s markets, reflects on all the solutions of TWT.

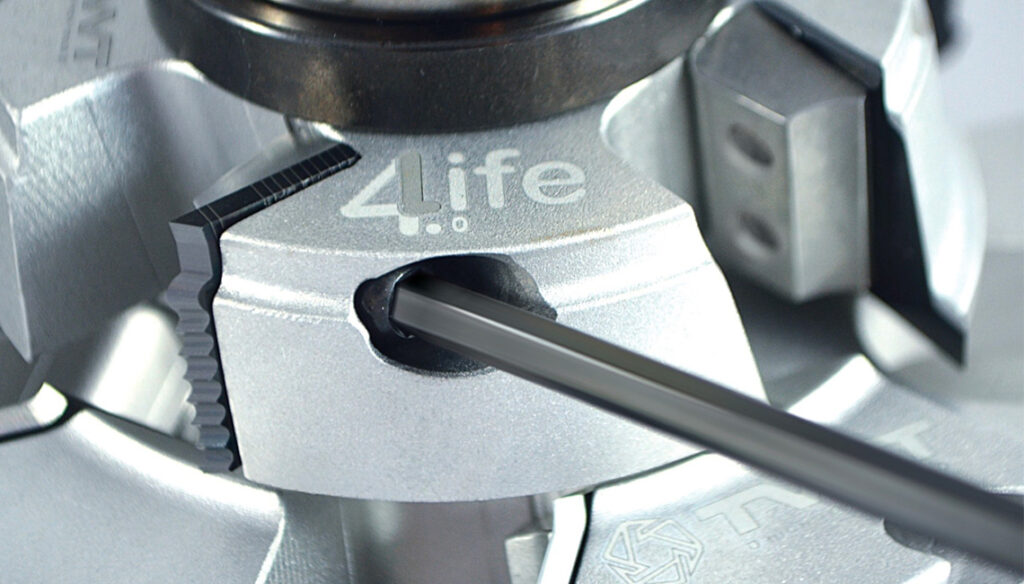

If Win&Doors is concerned, which is the tools production with high precision for the producing of wooden and wood-alu windows, the protagonist remains 4Life, innovative tool created by the assembly of four components at high precision: pre cutting knife, split cut, knife with double clearance and NaDia coating with DLC “Diamond Like Carbon” technology.

The NaDia coating is the second offering area based on nanostructure coatings for cut inserts. It’s a coating with a carbon base with a wide application spectrum. It is applied on finished details, maintaining the superficial finishing state. The elevates hardness comes from the simultaneous presence of hybridized carbon sp2 (graphite) and sp3 (diamond). Graphite determines the fluidity, the diamond determines the hardness.

NaDia is formed by 12 layers, with a total thickness of 1,2-1,5μ. Thickness, result of a long research, permits the cutting edge to stay extremely sharp, a fundamental specification of the wood’s cut, and it does not create the “elbow” effect on the cutting edge, increasing it’s duration.

The benefits offered by NaDia treatment are a lot: better finishing granted by a very low friction, increase of velocity without compromising the performance of the tool, a longer duration and a big reduction of the changing operations.

In this way the machines stops are considerably reduced. The performance of the cutting edge overtakes in percentage 250% arriving at 300%, resetting the costs of maintenance.

“At Ligna we will present even innovations which are in the GlobalTools programme” explains Nicola Pedrotti,manager of GlobalTools and Marketing of TWT. “Among this stands out CORAL’19, a new finishing edge banding with only one insert in DP, interchangeable and self-locating, that could be used on every machine on the market. It offers one substitution of the insert, fast and precise, guaranteeing continuity and fast working, aim while cutting an quality in finishing, zero vibrations and reduced noise production during the working period.

TWTWeb, a software which cares about clients

The spirit of the Industria 4.0 get realised even in TWTWeb, a software developed by the company to manage the spare parts, but which suggests the producer which tool should he use as support.

In TWTWeb we can also find data about products of TWT, to easily project the different types of windows, and the codes of the replacements TWT of the client in the storage sector. The client will have an instrument which will be able to order the replacements, avoiding stops of production, will be able to to know automatically the replacements arriving and already arrived. With an extra form, the client will be informed when an element has already worked too much and must be replaced.

Other instruments in the packets will let you do:

- 3D presentations and product rendering;

- 2D designs, with a description with the smallest details of it;

- Manage the order with different bases (glasses, wood, components, ecc,) and cut sizes.