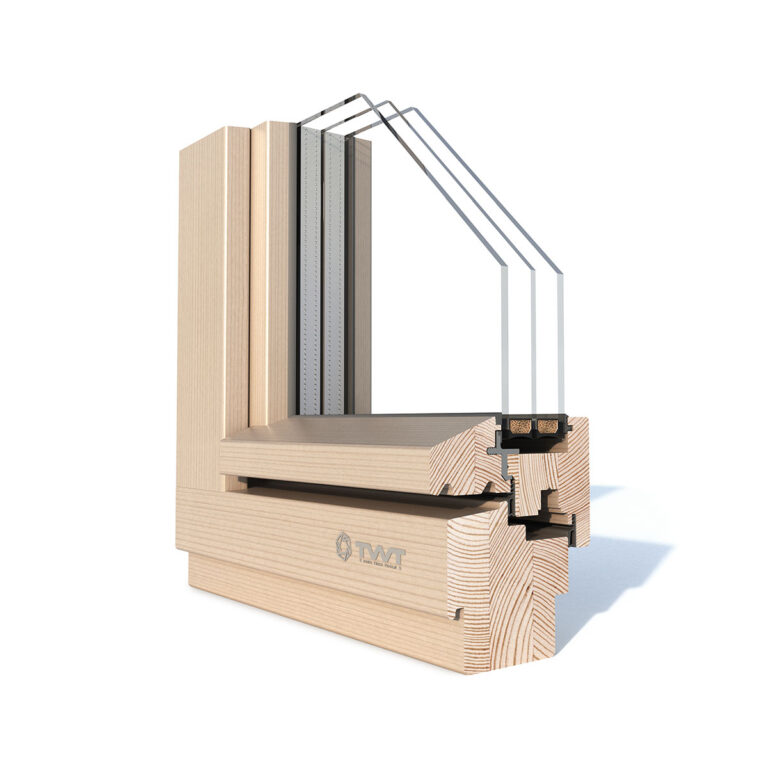

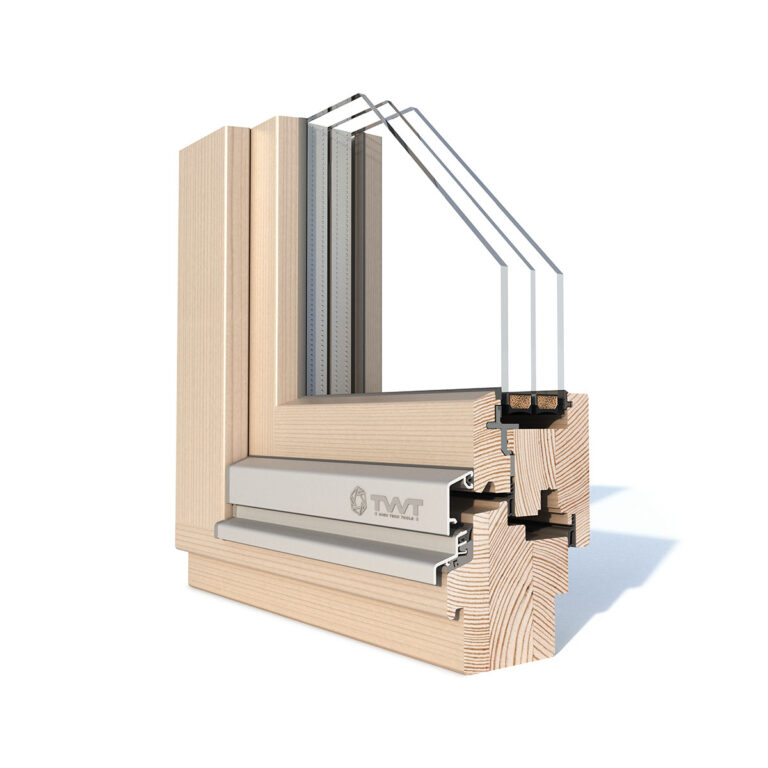

TWT Style IV80 Legno

The TWT Style IV80 Wood system is the result of a technical, production and market study carried out by our subsidiary in Germany, conducted together with TWT Engineering, based on all its experience and expertise in managing R&D processes in the field of wooden window and door systems.

This system, therefore, is the result of over 40 years of experience in solving the production aspects of windows and doors and of collaboration with renowned manufacturing companies. A system that can keep the production of every window and door manufacturer one step ahead of the competition.

Cutting technologies / Cutter systems

Window systems

Resources

Who we are

Cutting technologies / Cutter systems

Window systems

Vat nr: 02434730228

This website uses cookies to improve your experience while you navigate through the website.

View the Cookie Policy View the Personal Data Policy

Google Analytics is a web analytics service provided by Google Ireland Limited ("Google"). Google uses the collected personal data to track and examine the usage of this website, compile reports on its activities, and share them with other Google services. Google may use your personal data to contextualize and personalize the ads of its advertising network. This integration of Google Analytics anonymizes your IP address.

Place of processing: Ireland – Privacy Policy – Opt Out.

Google Maps is a maps visualization service provided by Google Ireland Limited. This service is used to incorporate content of this kind on its pages.

Personal data that are processed: Tracker; Usage Data.

Place of processing: Ireland – Privacy Policy.

Google Fonts is a service used to display font styles operated by Google Ireland Limited and serves to integrate such content into its pages.

Personal Information processed: Usage Data; Tracker

Place of processing: Ireland – Privacy Policy.