Ligna 2019 will be the perfect showcase to present the TWT-Style project to manufacturers of wooden windows. TWT- Style is the result of a technical, production and market study carried out by our branch in Germany, which has been joined by the TWT Engineering office with all his experience and competence in the management of R&D processes in the world of wooden frames.

Recognizing market trends early is essential if you want to have the ambition to be recognized as an innovator in your industry. TWT has always been in step with the times, and the numerous technological and design innovations developed over the years are proof of this.

Ligna 2019 will be the perfect showcase to present the TWT-Style project to manufacturers of wooden windows. TWT- Style is the result of a technical, production and market study carried out by our branch in Germany, which has been joined by the TWT Engineering office with all his experience and competence in the management of R&D processes in the world of wooden frames.

TWT-Style, therefore, is the result of over 40 years of experience in solving the productive aspects of doors and windows and of collaboration with renowned manufacturing companies. TWT-Style will make the production of each window manufacturer a step ahead of the competition.

TWT-Style offers 5 great advantages:

- The possibility of applying dry glazing on internal side. The solutions used in TWT-Style windows allow for dry glazing on the inside part of the window. This solution eliminates the expensive sealing process and, at the same time, reduces the production time. It has also a very positive effect on the appearance of the window and the aesthetics of its implementation. The problem related to the quality of glazing with silicone ceases to exist at this time.

- The possibility of easy production of two-color windows. The constructional solution of TWT-Style windows allows you to forget about the difficult and time-consuming performance of two-color windows. This results in significant savings thanks to the facilitation of work organization in painting departments.

- Higher tightness and resistance to wind load. The glass mounting bracket included in the TWT-Style system allows pre-compression of the glass and obtaining the appropriate pressure on the dry glazing gasket. The absence of the traditional glazing bead joint to the dry glazing ensures greater window rigidity and more resistance to break-in attempts.

- New architectural possibilities. The inner side of the window can be painted with totally bio-compatible products, enhancing the natural beauty of the wood with the guarantee of an environment free from dangerous substances. The external side can have a lacquered finish, ensuring durability and brilliance over time.

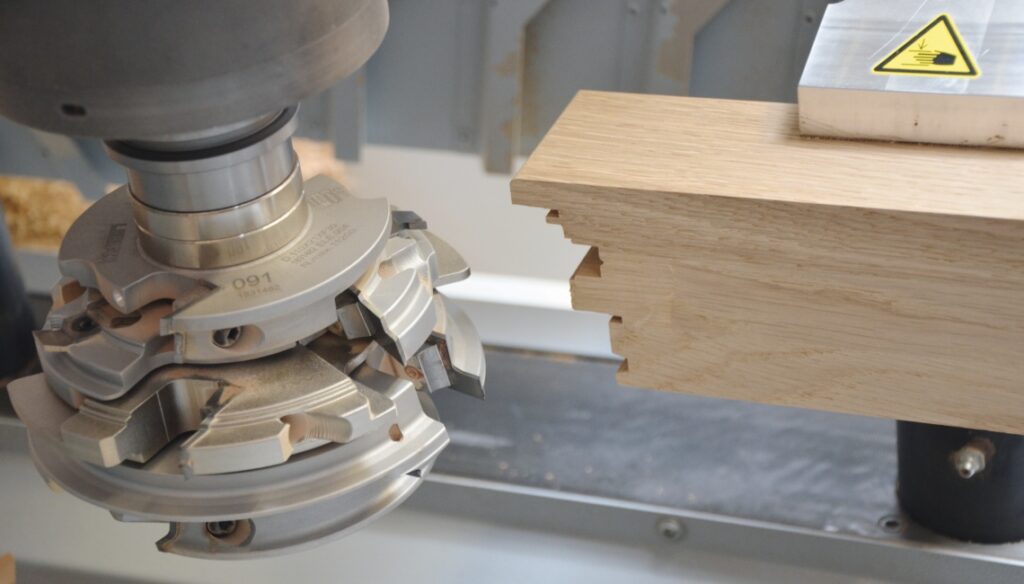

- The ease of manufacturing the glazing bead is easy. High ease of production of the glazing bead. The external glazing bead is profiled and recovered from window sash elements during their single passage through the machine. Thanks to this, a separate glazing bead profiling is eliminated on a four-sided planer and you can also forget the delicate 45° cutting operations.